|

REEFING Co., Ltd.

72, pr.Oktyabrya, Miass, Chelyabinsk region, RUSSIA, 456318 +7 (3513) 53 61 00 |

|

|

|

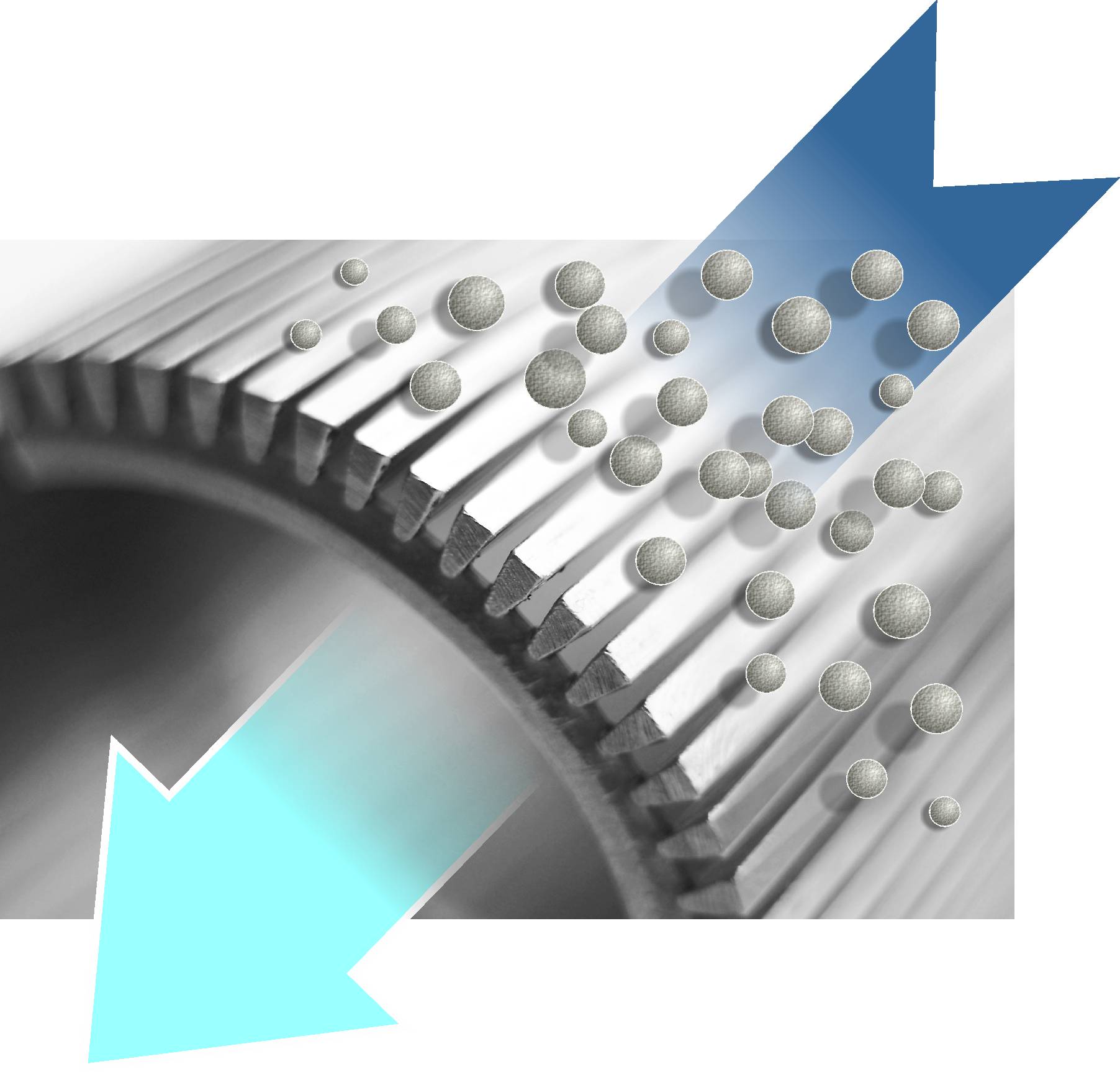

Slotted screen: design and advantages |

|

|

|