|

Priority area of our activities is engineering and manufacture of equipment (emerging technology samples) for petrochemical plants and oil refineries:

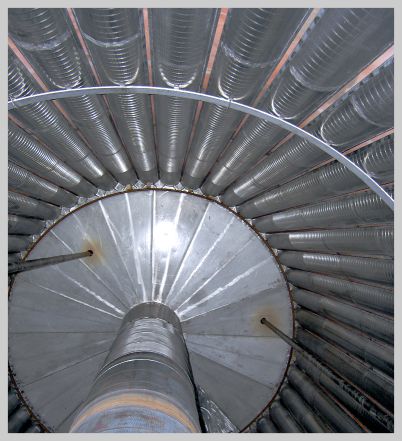

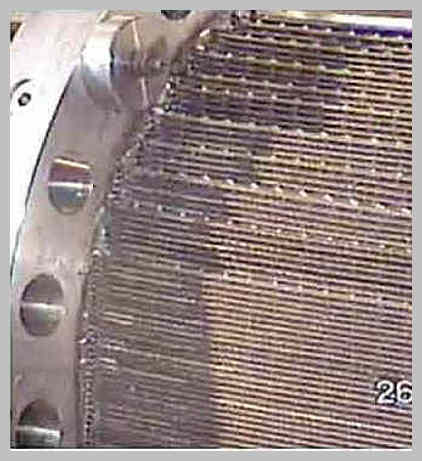

- Internals for reforming and hydrotreating reactors;

- Internals for column enthalpy exchangers;

- Internals for hydrocracking isomerization, isodewaxing, hydrogen generation, MTBE reactors;

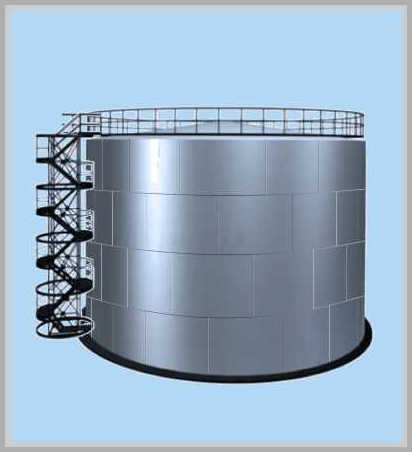

- Heat exchangers;

- Filter units for various operating fluids.

|

Equipment for Petrochemical and Oil Refining Plants

REEFING CO., Ltd expands towards its Clients with better understanding of their needs and goals, more comfortable communication irrespectively of any circumstances and mutually beneficial success. Probably sometimes we are well insisting and even emphatic in our urge to fully understand Clients requirements in details. However we believe that before contract signing it is necessary to clarify all specifics of both technical and operational nature of our equipment (assembling – dismantling comfort and simplicity within the shortest time).

|

We have asserted ourselves on the market of petrochemical and oil refining equipment manufacturers due to:

- creating and using a variety of unique technologies for equipment manufacture;

- established and loyal cooperation with partners including France (Johnson Screens);

- and, the most important, due to well-coordinated and qualified work of our team.

All these make the services provided by our company highly effective, and often the only possibility for tailor-made items. With pride we can say that these days many major petrochemical plants and refineries address REEFING specifically.

REEFING CO., Ltd is:

- new developments;

- tried and tested, solid products with long-term operation life;

- high quality of manufacturing;

- strict meeting contract obligations.

|